What is it like for an American to live in India?

Living in India as an American is a rollercoaster ride of vibrant colors, spicy food, and a cultural fiesta that is hard to rival! Every day is like a Bollywood movie with a dash of curry and a hint of yoga. You'll find yourself in the middle of a crowd, yet completely alone, a feeling that is both amusing and mind-boggling. It's like life turned up to 11 – the honking traffic, the rich traditions, the incredible diversity, all packaged in a country that is a unique blend of chaos and serenity. And don't get me started on the cows, they're the true VIPs here!

What do Indian couples do while having sex?

Exploring the intimate world of Indian couples, it's clear there's a diverse range of practices and preferences when it comes to sex, highly influenced by personal comfort, cultural nuances, and mutual consent. Just like anyone else, they engage in foreplay, different sexual positions, and express themselves openly. Some might also incorporate elements of the Kama Sutra, an ancient Indian text that discusses sexuality and eroticism. However, it's important to note that the emphasis on open communication and consent is paramount. Overall, the sexual experiences of Indian couples are as varied and unique as the individuals themselves.

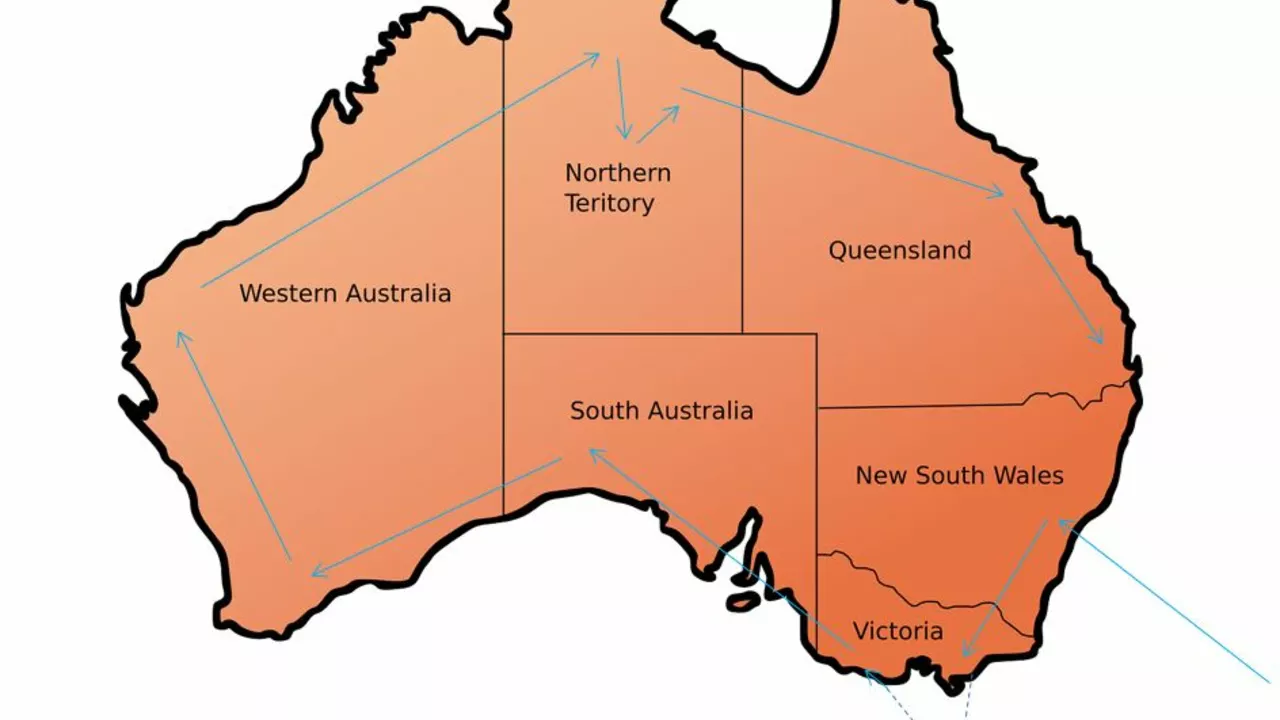

I hate my country, India. I love Australia. What should I do?

As an Indian, I find myself increasingly discontent with my country and drawn towards the lifestyle in Australia. There's a growing resentment in me towards the problems in India, while Australia's culture, lifestyle, and opportunities seem more appealing. The dilemma I face is immense, as it involves leaving my birthplace for a foreign land. I am torn between my love for Australia and my duty towards India. I'm contemplating my next steps, wondering if I should make the leap or stay put.

What are some of the 15 minutes Indian breakfast ideas?

There are several Indian breakfast ideas that you can whip up in just 15 minutes to start your day off right. For instance, poha, a light and healthy dish made from flattened rice, is a popular choice. Upma, a savory porridge from South India, is another quick and nutritious option. Alternatively, you could opt for aloo paratha, a filling potato-stuffed bread, or idlis, fluffy steamed rice cakes. These dishes are not only easy to make, but they're also incredibly flavorful and satisfying.

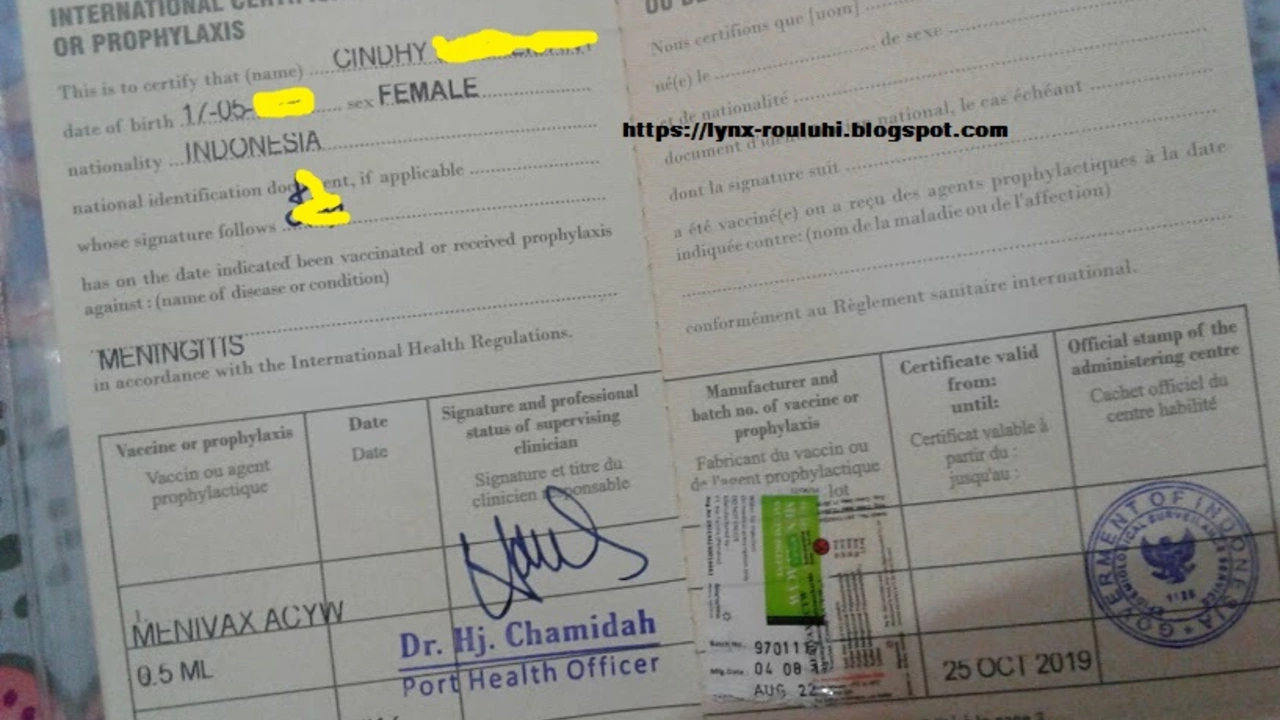

How to apply for a nationality certificate in India?

In India, applying for a nationality certificate involves a simple process. You start by filling out an application form from the District Magistrate Office. This form should be submitted with necessary documents, like proof of residency, birth certificate, and proof of Indian citizenship of parents. Once your application is approved, you'll need to take an oath of allegiance before the District Magistrate. Finally, you'll receive your nationality certificate, marking your official recognition as an Indian citizen.

French Homework Help

Struggling with French homework can really be a hassle, but don't worry, there's help out there. Various online platforms offer assistance with French grammar, vocabulary, and pronunciation. You can also find tutors who are native French speakers to guide you through your assignments. They not only help with homework but also enhance your understanding of the French culture. It's a great way to improve your language skills and get your homework done right.

What is it like for a vegetarian Indian to live in South Korea?

Living in South Korea as a vegetarian Indian has been a fascinating journey. Initially, it was challenging to find vegetarian options, as Korean cuisine is primarily meat-based. However, with time, I discovered several vegetarian-friendly restaurants and grocery stores offering a variety of vegan products. I also learnt to cook Indian food at home, which helped me stay connected with my roots. Although it required some adjustments, I've managed to maintain my vegetarian lifestyle in South Korea.

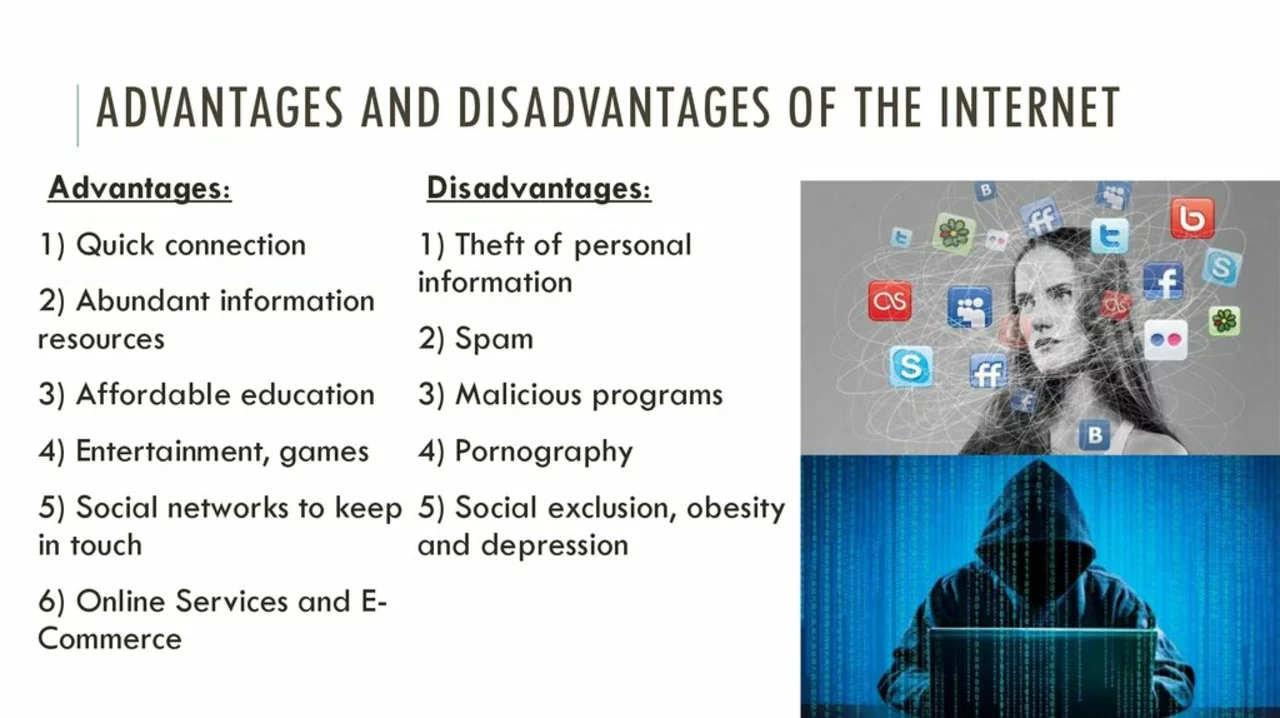

What are the pros and cons of living in Tamil Nadu?

As a resident of Tamil Nadu, I've experienced both the pros and cons of living here. On the positive side, Tamil Nadu boasts a rich cultural heritage, delicious cuisine, and stunning temples that attract tourists from around the world. Additionally, it offers excellent educational institutions and job opportunities, especially in the IT sector. However, the state also faces some drawbacks, such as high humidity and scorching summer heat, which can make daily life uncomfortable. Furthermore, the rapid urbanization and industrialization have led to increasing pollution and traffic congestion, impacting overall quality of life.

Why do Indian-Americans hate India and Indian culture?

As an Indian-American blogger, I've observed a certain level of disdain towards India and Indian culture from some within our community. There seem to be a few factors contributing to this mindset, such as a desire to distance oneself from traditions in order to assimilate into American society. Additionally, negative stereotypes and misconceptions about India can also play a role in fostering this animosity. However, it is important to recognize that not all Indian-Americans feel this way, and many of us take immense pride in our heritage. Ultimately, having a healthy understanding and appreciation for both cultures is key to forming a balanced identity.- 1

- 2